About Rotor Sails

Rotor Sails, traditionally known as Flettner Rotors, were first installed on ships in the 1920s after being invented by Anton Flettner. At the time, the technology was not widely adopted due to the rising popularity and low cost of diesel fuel. Now, 100 years later, this wind technology has garnered new interest in its ability to help lower emissions. Wind power is a safe, sustainable way to propel modern merchant ships.

Rotor Sails have demonstrated increased vessel efficiency, reducing fuel consumption, bunker costs and harmful emissions. Compared to other wind propulsion technologies, Rotor Sails offer a much greater thrust force to propel the ship per square metre of sail area. This means they can be made more cost effectively and with less impact on vessel operation than traditional sails or wings.

Why we’re the right fit for your vessel

Lightweight

Anemoi Rotor Sails are manufactured from highly engineered lightweight composites to achieve excellent performance with minimised additional weight. At the heart of the Rotor Sail is a strong steel tower which carries all the loads safely into the ship structure.

Optimised for all weathers

Our Rotors are designed to withstand the most severe weather conditions, in line with Class Requirements. Our Rotors can operate in heavy seas and wind speeds of up to 35m/s (70kts). In extreme conditions outside of the operating limits of the Rotor Sails, they automatically turn off. Unlike other wind technologies, reefing is not required.

Ex-rating

For installation on vessels with hazardous zones (e.g. Tankers and Gas Carriers), Anemoi offer an EX-Rated Rotor Sail option.

Regulatory Compliance

A 5-30% reduction in harmful emissions including CO2, SOx, NOx benefits the environment and helps vessels adhere to regulatory guidelines and targets. Rotor Sails positively impact the EEDI score of a newbuild vessel and can provide a route to compliance with upcoming 2025 Phase 3 regulations, and improve potential operational indicators for retrofit installations (e.g. EEXI and CII).

Verified Thrust & Reporting

Performance reporting is generated using real time data transmission and verified against thrust data from Anemoi’s full-scale UK based testing facility.

Automated & Easy to Operate

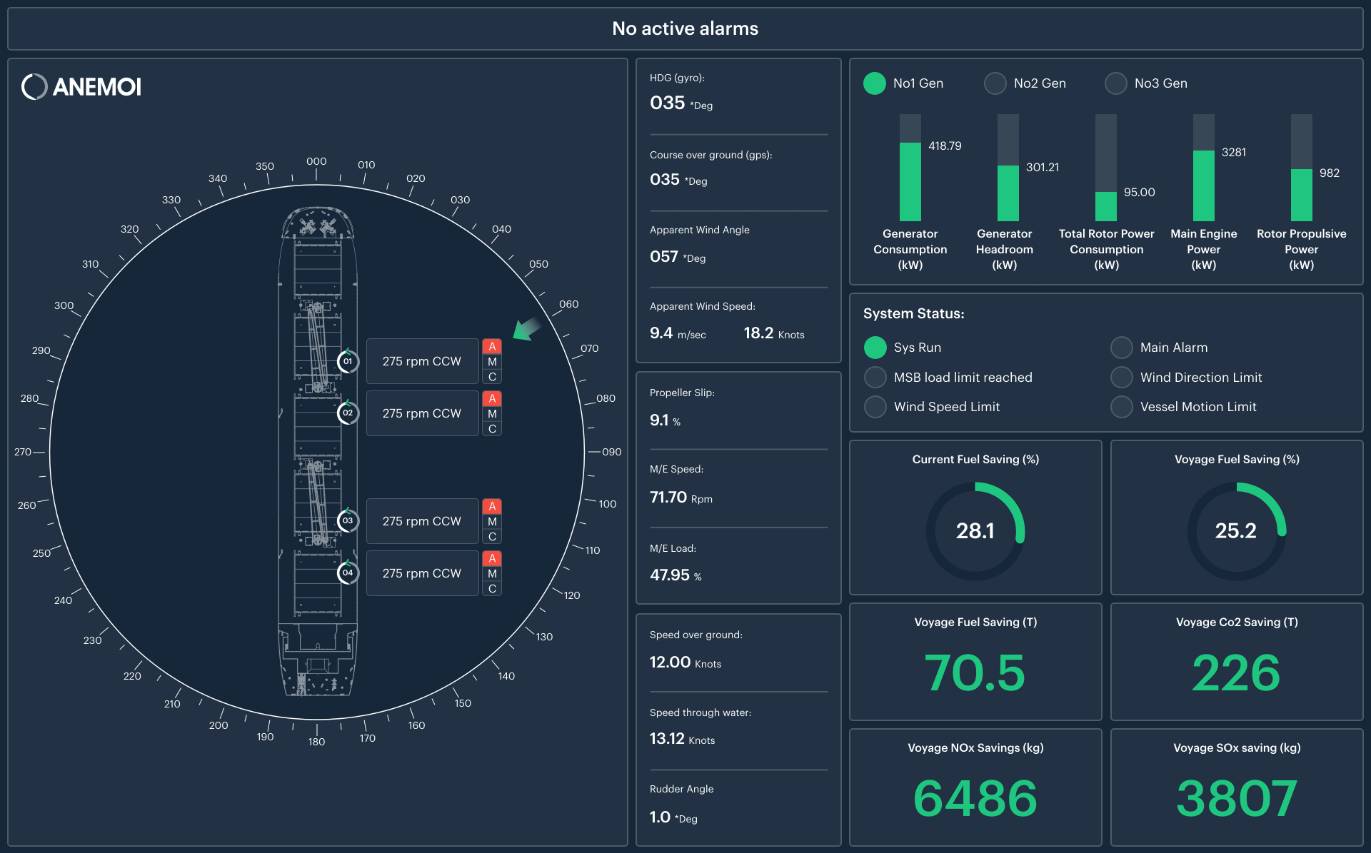

We offer fully automated and optimised operations using Anemoi’s Control System located on the bridge.

Movable Asset

Anemoi Rotor Sails can be redeployed between vessels as driven by business requirements so owners can feel assured of the longevity of investment, securing payback.

Suitable for Most Vessel Types

Rotor Sails are suitable for most vessel types, including newbuild and retrofit, Bulk Carriers (geared and gearless), Tankers, LNG and LPG Carriers, Ferries and RoRos.

Safe & Robust

Anemoi Systems are designed and certified in accordance with leading classification society rules, ensuring compliance with the highest marine quality standards.

Rotor sizes

The size and number of Rotor Sails installed is determined by vessel size, available deck space and operating profile. We work closely with clients during the technical feasibility stage of the project to ensure maximum performance is achieved.

Deployment Systems

Anemoi has designed patented systems which allow the Rotor Sails to be moved or folded on the deck. Being able to move or fold the Rotor Sails on deck in a matter of minutes removes any impact on cargo operations and mitigates concerns about air draft.

Technical & Equipment

The Anemoi Rotor Sail System is comprised of the Rotor Sail itself, the Foundation, Deployment System (if required), wind sensors and Electrical and Control system. The location of the equipment is marked on the following diagram.

Materials

As shown in the diagram, the 4 main components of our Rotor Sails are the “Rotor” (the cylindrical, rotating part), the Tower, Upper and Lower bearings, and the electrical drive. The “Rotor” is made from lightweight composite material and the Tower is a steel column structure.

We use these materials to ensure maximum performance of our Rotor Sails and to withstand all weather conditions. Choosing lightweight materials also means our systems are typically less than 0.1% of vessel deadweight.

Electrical & Control System

The Rotor Sails have a Control Station located on the bridge. This automatically controls the speed and direction of the Rotor Sails, as well as monitoring the performance and status of the system. Our Control System is designed to maximise performance and minimise crew input with automated speed and direction setting, equipment monitoring and safety shutdowns.

The electrical input power requirements of the Rotor Sails varies depending on the Rotor speed, which is dependent on the wind speed. The average power input of one Rotor Sail is typically ~40% of the rated power of the motor when operating. For example, a Rotor Sail with a 75kW motor would use 30kW on average.

Maintenance

Anemoi systems are built to last and have low maintenance costs. Regular maintenance includes the following activities:

- Periodic visual inspection of components

- Bearing lubrication replacement (approx. every 6 months)

- Greasing other mechanical components (approx. every 6 months)

- Annual inspections carried out at the same time as standard vessel survey